|

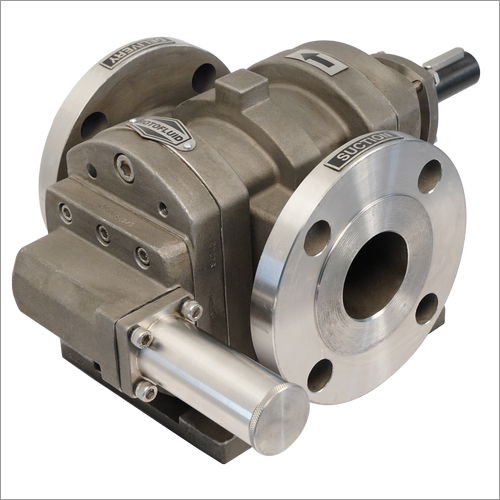

Lube Oil Transfer Gear Pump

Price 2500.00 INR/ Piece

Lube Oil Transfer Gear Pump Specification

- Flow Rate

- 30 LPM to 500 LPM

- Inlet/Outlet

- 1 to 4 BSP/NPT/Flanged

- Frequency

- 50Hz / 60Hz

- Noise Level

- Low

- Caliber

- Customizable as per requirement

- Head Size

- Up to 70 m

- Features

- Robust construction, Compact design, Leak-proof, Easy maintenance

- Discharge Pressure

- Up to 10 bar

- Theory

- Rotary Gear Pump

- Control System

- Manual / Automatic

- Voltage

- 220V / 380V / 415V, 50Hz / 60Hz

- Speed

- 960 to 2880 RPM

- Mounting Type

- Base Plate / Foot Mounted

- Max Suction

- Up to 5 m

- Working Temperature

- -10C to +80C

- Material

- Cast Iron / SS 304 / SS 316

- Structure

- Simplex / Duplex

- Power

- 0.5 HP to 15 HP

- Standard

- ISI / ISO 9001:2015

- Fuel Type

- Oil

- Pressure

- 3 to 10 bar

- Usage

- Lube Oil, FO, Diesel, Hydraulic Oil, Light/Heavy Oil transfer

- Application

- Industrial, Marine, Oil Storage, Power Plants

- Suction Type

- Positive Displacement

- Seals Type

- Mechanical Seal / Gland Packing

- Priming

- Self-priming

- Pump Type

- External/Internal Gear

- Capacity

- Up to 30 m/hr

- Drive Type

- Electric Motor / Engine Driven

- Shaft Material

- EN8 / SS

- Rotation Direction

- Clockwise or Counter-Clockwise

- Duty Cycle

- Continuous

- Paint Finish

- Anti-Corrosive Coating

- Coupling Type

- Flexible / Rigid

- Viscosity Range

- Up to 100,000 SSU

Lube Oil Transfer Gear Pump Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 3-5 Days

About Lube Oil Transfer Gear Pump

Superior Versatility for Oil Transfer

Designed to accommodate a broad viscosity range and multiple oil types, this gear pump performs seamlessly in a variety of industries, from marine to power generation. Its ability to operate clockwise or counter-clockwise, along with customizable inlet/outlet options and compatible mounts, ensures easy integration into existing systems. High resistance to corrosion and robust components make it suitable for demanding environments.

Engineered for Reliability and Longevity

Constructed with EN8 or stainless steel, and finished with an anti-corrosive coating, the pump withstands harsh industrial conditions. The self-priming, positive displacement design supports continuous duty cycles, while advanced sealing options minimize leaks. Low noise operation and straightforward maintenance contribute to a dependable and user-friendly solution for oil transfer needs.

Flexible Power and Control Options

Offering compatibility with electric motors or engines, and operating at various voltages and frequencies (220V/380V/415V, 50Hz or 60Hz), the gear pump adapts to different power sources and control systems, whether manual or automatic. It comes in both simplex and duplex structures, making it a fitting choice for standard or demanding multi-shift operations.

FAQs of Lube Oil Transfer Gear Pump:

Q: How can I select the correct gear pump configuration for my oil transfer application?

A: To choose the right configuration, determine your required flow rate, pressure, viscosity range, and desired coupling type. Consider the material compatibility (such as Cast Iron or SS 316) based on the type of oil, and select appropriate inlet/outlet sizes. Our pumps are customizable to meet varied industrial or marine requirements.Q: What maintenance process should be followed for this lube oil transfer gear pump?

A: Routine maintenance involves checking the mechanical seal or gland packing for leaks, inspecting the shaft alignment, and ensuring that anti-corrosive coatings are intact. Periodically clean filters, assess couplings and replace worn components as necessary to sustain optimal performance.Q: When is it advisable to choose flexible coupling over rigid coupling for this pump?

A: Flexible couplings are recommended when there might be shaft misalignment or vibration, as they can absorb shocks and compensate for minor positioning errors. Rigid couplings are suitable for installations with precise alignment and minimal vibration, providing a more direct power transfer.Q: Where is this lube oil transfer gear pump typically used?

A: This pump is widely used in industrial plants, marine vessels, oil storage facilities, power plants, and anywhere efficient transfer of lube oil, hydraulic oil, fuel oil, or diesel is required. Its robust design makes it suitable for demanding and continuous operation environments.Q: What types of control systems are available for this gear pump?

A: The pump supports both manual and automatic control options. Depending on your operations requirements, you can choose manual controls for basic operation or integrate automatic systems for enhanced efficiency, monitoring, and error reduction in complex or large-scale setups.Q: How does the self-priming feature benefit the oil transfer process?

A: Self-priming capability enables the pump to evacuate air from the system and start pumping fluid without external priming, reducing startup delays and simplifying installation. This is particularly advantageous when transferring oils from tanks or below-ground sumps.Q: What are the main benefits of using this gear pump for oil transfer?

A: Key benefits include reliable leak-proof performance, easy maintenance, adaptability to a wide viscosity range, low noise operation, and robust construction. The pumps compact design, compliance with ISI and ISO 9001:2015 standards, and wide customization options ensure long-lasting and efficient service in various industrial contexts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gear Pumps Category

Loading Unloading Gear Pumps

Minimum Order Quantity : 01 Piece

Suction Type : Positive Suction

Flow Rate : 25 LPM to 5000 LPH

Priming : Self Priming

Inlet/Outlet : 25mm to 80mm

Gear Box Oil Lubrication Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive Displacement

Flow Rate : 13 LPM

Priming : Selfpriming

Inlet/Outlet : 3/8 BSP (customizable)

Three Phase Helical Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive displacement

Flow Rate : Up to 120 LPM

Priming : Self priming

Inlet/Outlet : 1 x 1 BSP (customizable)

Corrosive Chemical Gear Pump

Price 2500.00 INR / Piece

Minimum Order Quantity : 1 Piece

Suction Type : Positive Suction

Flow Rate : 0.5 m3/h to 30 m3/h

Priming : Self Priming

Inlet/Outlet : Threaded / Flanged

|

FLUID TECH SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry